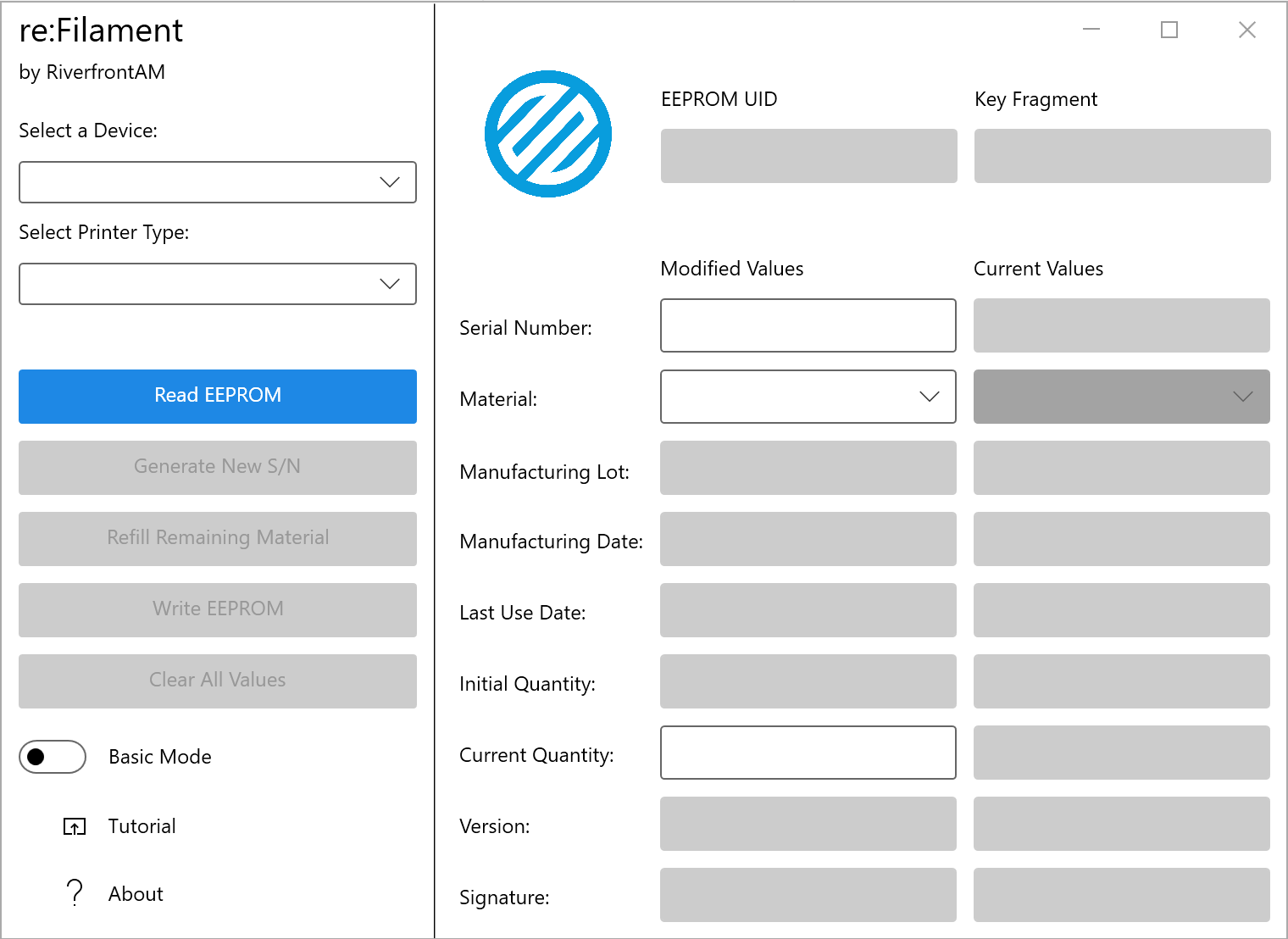

This device was designed to be able to hack and refill the EEPROM chips found in the material cartridges for the Stratasys Dimension® and Fortus® lineups of 3D printers. The included software (PC program) will allow you to change material type and material quantity on these cartridges, therefore letting you use any compatible 3rd party filament on your machine at a fraction of OEM costs. Couple this with our material unlock service and you can run virtually any filament in your machine at the lowest cost possible. This device works with stock machines, no software or hardware hacks are required.

- Dimension SHDM-1000

- Dimension 768 BST/SST

- Dimension 1200 BST/SST

- Dimension Elite 1200ES

- Dimension Elite

- Fortus 250mc

- Fortus 360mc

- Fortus 400mc

- Fortus 900mc (Classic)

- ABS P400

- ABS P430

- ABS P430XL

- ABSplus

- P400R

- P400SR

- ABS-M30

- Nylon 12

- Polycarbonate

- Ultem 1010

- Ultem 9085

- Ultem Support

- SR20

- SR30

- SR35

- SR100

- SR110

- And many more

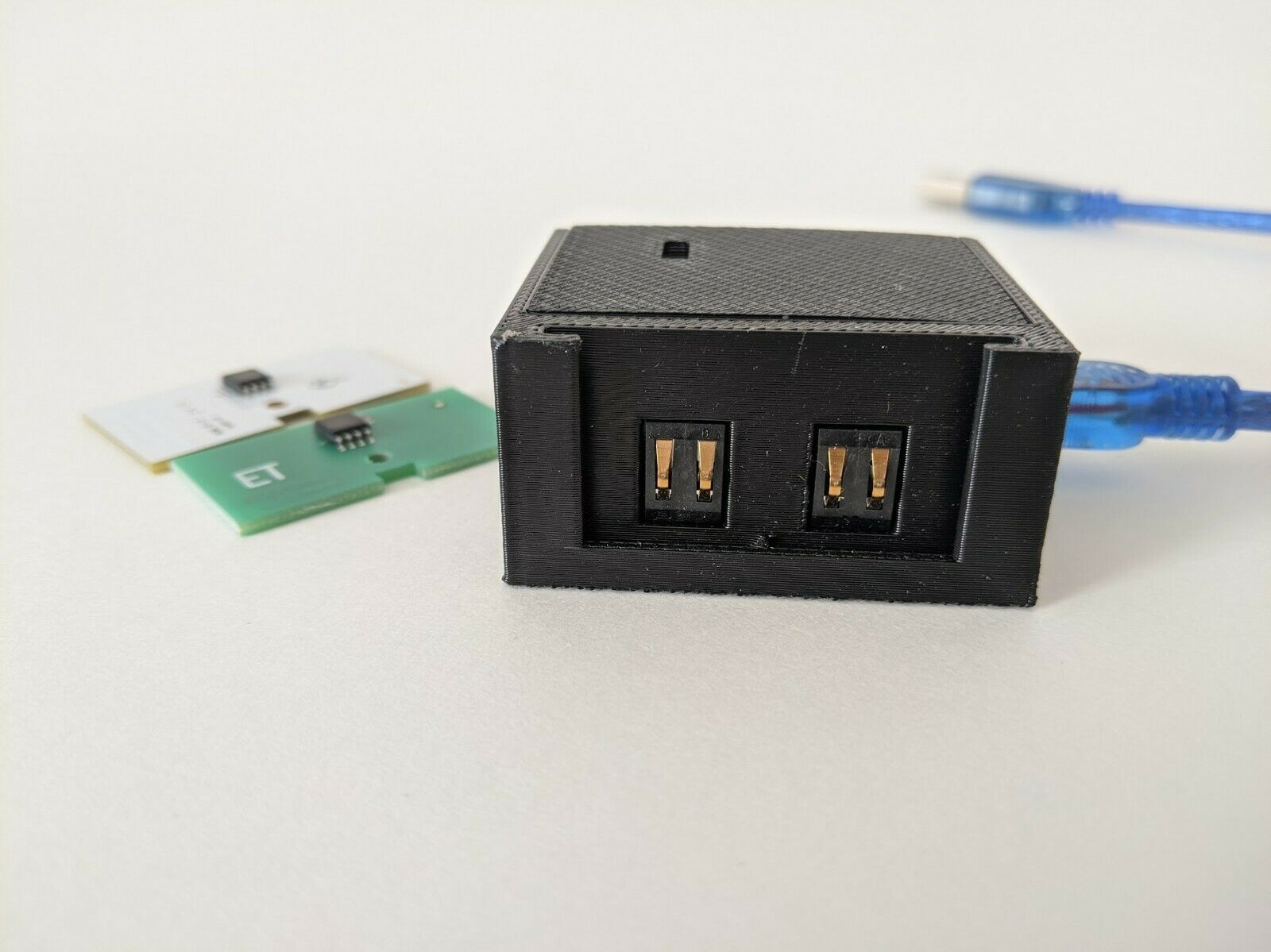

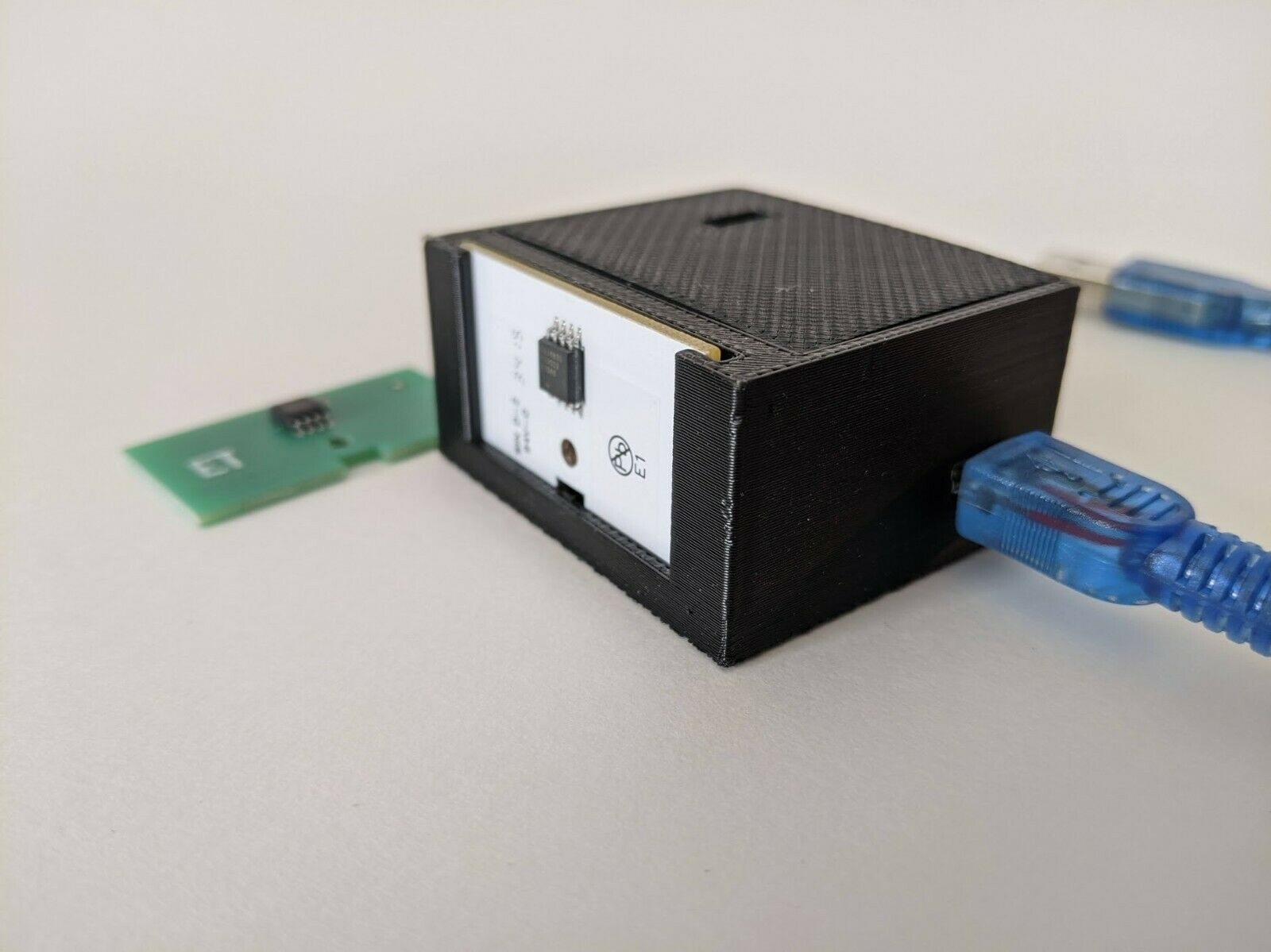

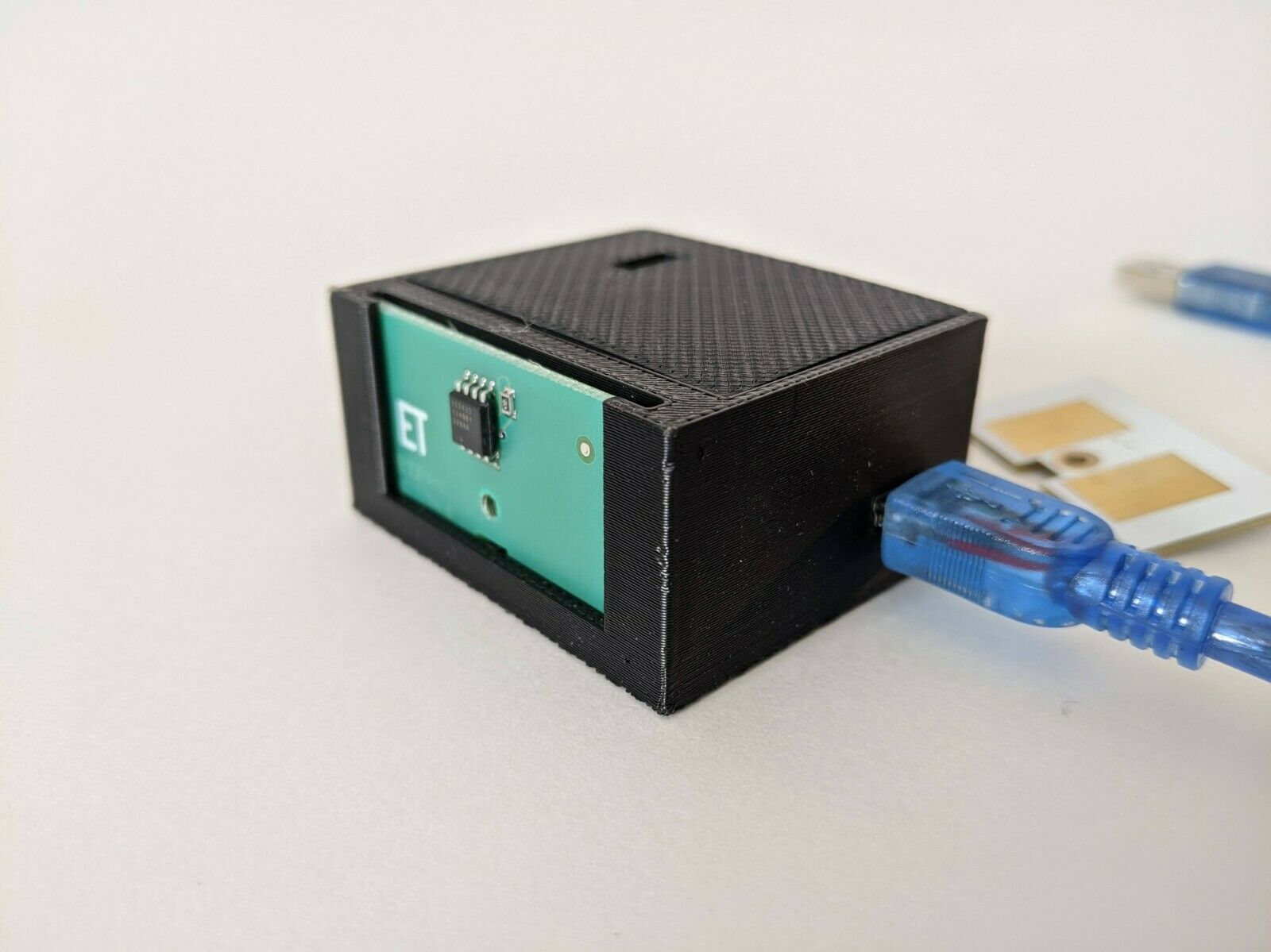

* These units are usually made to order, please allow a few days for assembly, testing and shipping. The color of the housing is subject to change depending on the color of the material we have on hand at the time. Product includes EEPROM reader device and cable, as well as the software required to run the device. No EEPROM chips are included.

FAQ

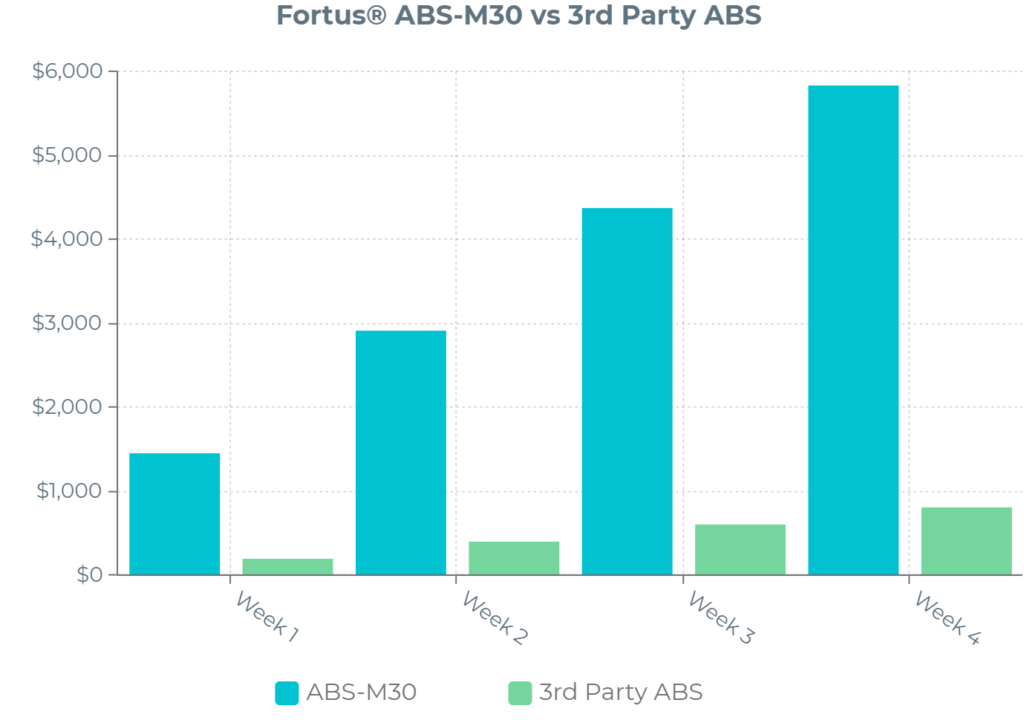

The main benefit of using this device is to allow you to run 3rd party filaments on your machine, drastically bringing down the cost of material. Some of the machines will also allow you to configure larger starting quantities for your material, therefore letting you run massive 5-10kg spools and eliminating the constant downtime in between changing out empty spools.

First you will need to plug the device into a PC and download the required software. Afterwards you’ll pull the chip out of the canister and plug it into the device. The software will then allow you to refill the empty chip, as well as change the material type if you desire. After refilling the chip and making any additional changes, you can then plug the chip back into the canister and load it with any material of your choosing.